Textile prints

The best processes for your fabrics and garments

CORROSION

We apply chemicals to the surface of the fabric, creating a controlled corrosion or decomposition effect, resulting in an irregular, textured pattern that mimics the appearance of corroded metal.

DEVOURED

We treat garments with chemicals to create a visual effect of transparency and texture by selectively removing fibers, resulting in intricate and eye-catching designs on your garments.

DISPERSOS

We print designs on polyester, allowing the transfer of vibrant, high-resolution colors to fabrics, creating durable, brightly colored, high-resolution prints that are resistant to washing and wear, and allow for breathable fabrics. With a dispersed finish you can achieve a large, detailed design print without affecting the softness or texture of the fabric.

GLITTER

We treat our fabrics to reduce the formation of lint or pilling, which can give a worn and unkempt appearance to the fabric.

LACQUERS

We perform a controlled application of enzymes on the surface of the fabric, which act on the textile fibers, eliminating loose fibers, improving the uniformity of the fabric and smoothing the surface of the fabric.

Biopolishing is one of the most popular finishes due to its environmental benefits and its ability to improve fabric quality.

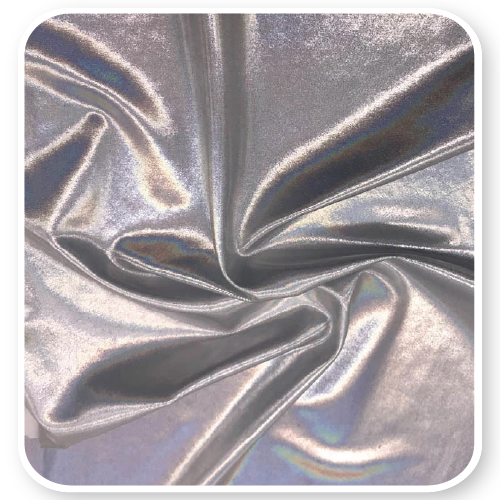

METALLICS

We use abrasive tools to rub or brush the surface of the fabric. This controlled abrasion removes surface fibers, creating a fuzzy, smooth, emery-like appearance. The result is a fabric with a soft feel and a slightly aged look.

NACARADOS

We achieve this finish by applying special chemicals and additives to the fabric during the manufacturing process or by subsequent treatments to absorb and reflect UV rays, reducing the amount of radiation that passes through the fabric and reaches the skin.

SCHEDULE A SESSION

Get to know our multiple colors, finishes and prints that will make you stand out in the industry.

PIGMENTS

We use abrasive tools to rub or brush the surface of the fabric. This controlled abrasion removes surface fibers, creating a fuzzy, smooth, emery-like appearance. The result is a fabric with a soft feel and a slightly aged look.

REAGENTS

We achieve this finish by applying special chemicals and additives to the fabric during the manufacturing process or by subsequent treatments to absorb and reflect UV rays, reducing the amount of radiation that passes through the fabric and reaches the skin.

THERMOCOLOR

We use abrasive tools to rub or brush the surface of the fabric. This controlled abrasion removes surface fibers, creating a fuzzy, smooth, emery-like appearance. The result is a fabric with a soft feel and a slightly aged look.

CONTACT

Let’s talk about your project!

We have the experience, technology, quality, creativity and personnel to make it possible.

Write to us at

info@grupovivatex.com.mx

Santa Fe

Avenida Santa Fe 505, Cruz Manca, C.P. 01219, CDMX.

Telephone: (55) 5261 4444

Toluca

Josefa Ortiz de Domínguez 105, Francisco I. Madero, C.P. 52016, San Mateo Atenco, State of Mexico.

Telephone: (722) 273 0505